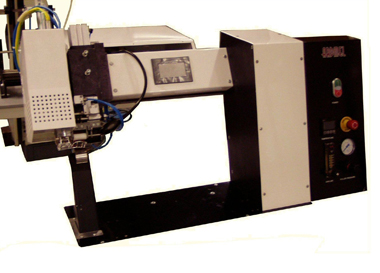

Mk501 Seam Sealer

The Mk501 Seam sealer is specially designed to provide ease of

operation, consistency and quality complete with a range of optional

modular attachments to meet today's requirements for more flexible

equipment.

Applications:

Outerwear, Underwear, Sportswear, rucksacks, footwear, tents,

balloons, car components, awnings, boats, inflatables, Balloons,

protective wear, clean room garments, medical industry and filter bags.

Quality and Accuracy:

The simple to use and comprehensive control system includes a digital dual display temperature controller and HMI display unit. The HMI panel is used for setting speed and operating parameters. The dual display temperature controller has an accuracy of ±1% and interacts with the machine's PLC to ensure the heater is at the set temperature. If the correct temperature has not been reached the machine is disabled.

Operator Visibility:

The angled post with low profile scissor ensure increased visibility

for the operator

Skip Prevention and Roller Reverse feature:

Adjustable delay timers and drive stop can be set to eliminate

“Skipping” during starting and stopping while sealing long seams. In

addition the roller reverse facility can be selected. When depressed,

the rollers will reverse slightly while pausing for garment readjustment

on a long seam. This repositions the tape/seam joint under the heater.

Knee Press Feature:

This clever function allows the operator to slow the machine down on heavy materials such as 3-layer fabrics where the cross over seams need more pressure and heat. Normally in production the garment would be removed after tape sealing and re-stamped on another machine in these areas where seam tape is prone to lifting. By using this feature this additional operation is removed from the manufacturing process.

Optional Modular Attachments:

The lower quill and heater assemblies can be readily interchanged or re-positioned to provide quick change over with different configurations.

Cylinder Arm : Easy sealing of circular areas such as cuffs and

tubes.

Horizontal Heater: Provides easy lap seam welding of PVC and vinyl

materials

50mm Welding Kit: Wider welding ability especially for heat sealing of reflective tapes.

Skinny taping Kit : Narrow taping for ultrasonic seams on stretch and non stretch materials.

Slim Quill : Provides sealing of curves with tighter radius. Ideal for shoes and gloves.

Looking after our planet:

The Mk901 is the most efficient and energy saving machine on the market today. Our adjustable energy saving function kicks in when the machine has been lying idle eliminating wastage of precious resources. The low air consumption of 3 C.F.M of which most is used through the heater means that the power consumption is also kept to a minimum.

Keeping it simple

Engineering reliable and easy maintenance machines is key to our success. Ensuring that our equipment has very little down time and that problem solving is never over complicated that's why you will not find unnecessary electronics and software in our machines which can heighten the risk of failure and expensive parts replacements.